This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

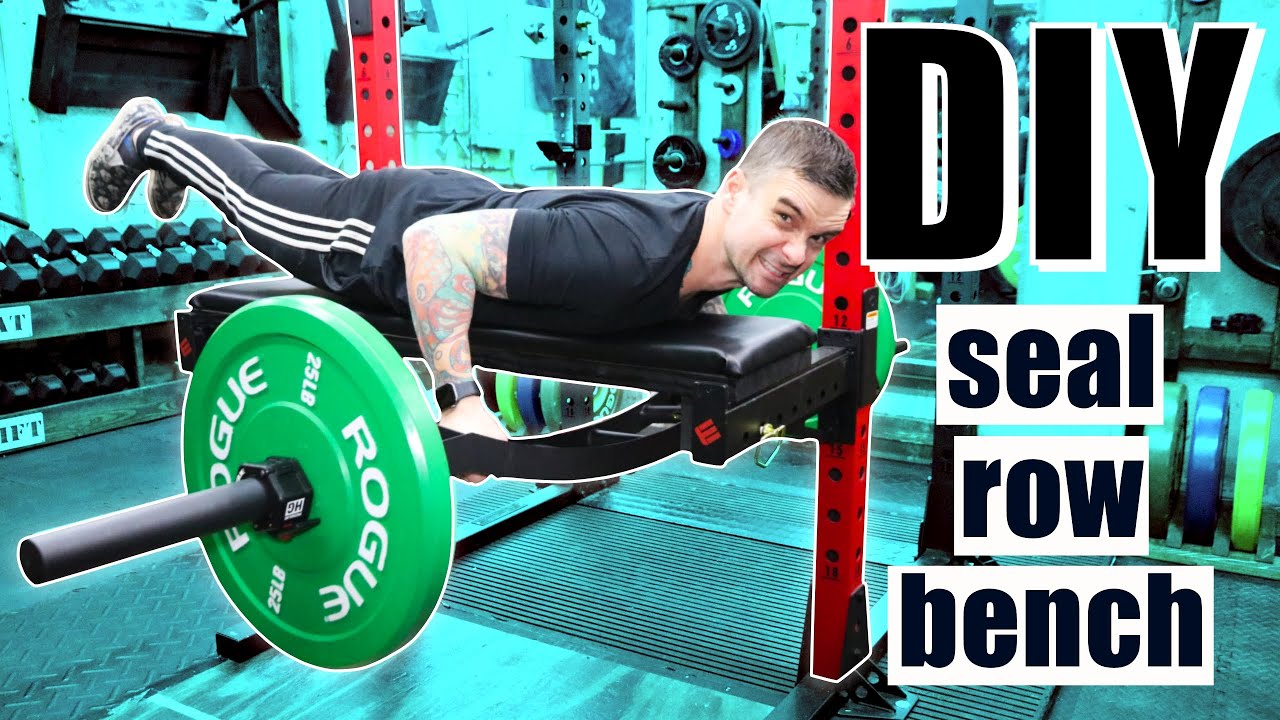

hello everyone welcome back to another

diy gym equipment video my name is Kyle and this week we're going to make a seal

row bench attachment for your power rack what are seal rows? they're rows that you perform

while laying horizontal the word seal comes from the tendency of the lifter to kick their legs

up while they're doing the lift there are many benefits to doing seal rows but the main benefit

is full activation of the lats while putting little to no pressure on the lower back there are

lots of options for purchasing a standalone seal row bench but they tend to be pretty pricey and

take up a lot of space that's why this is such a great build the materials cost me about 30 bucks

because i already had a lot of this stuff laying around if you're starting from scratch and buying

all the materials new it'll cost you around eighty to ninety dollars the total size is forty eight

by twelve by seven inches and it weighs just under twenty five pounds when i'm not using it

it conveniently fits behind my functional trainer it's a pretty versatile piece of equipment in

addition to seal rows i've also used it as an adjustable high plyo box it works great for hip

thrusts box squats body weight reverse hypers split squats it's the perfect support for my

preacher pad dumbbell step-ups ghd sit-ups and i can use it to turn my gym into a home office

okay enough chit chat let's build this thing safety first wear a dust mask wear eye protection

wear hearing protection diy projects are awesome but being safe is even more awesome i won't

be providing a cut list for this project all the dimensions will be based on your power rack

but i'll show you how to get the dimensions that you need to build this the full list of tools and

materials that i use is located in the description of this video as a bonus if you purchase from

any of those links it goes towards helping to support this channel i start off by cutting my 2

by 12.

You'll want to measure the distance to the outside of each safety for me it's 48 inches i'm

using a sliding miter saw but you can also use a circular saw for this next i find a piece of scrap

2×4 and cut it to two 10 inch pieces when in use i want to secure this to my safeties using hitch

pins i hold a 2×4 up to my safety and mark one of the holes with a pencil when drilling i stack

them and clamp them so the holes are identical these holes will allow me to attach to

my safety spotter arms using hitch pins by the way if you're watching this and thinking

it's a lot of work or you don't want to invest in the tools to build this that's okay too rogue

actually sells something very similar it's called the monster utility seat and it is solid as a

rock i have a link to it in the description of this video in terms of placing your two by fours

they'll go on the insides of the safeties you can place your two by twelve on the safeties and

mark it that way or just measure the safeties i'll be attaching the two by fours to the two by

twelve using three inch lag screws i use one and an eighth inch forstner bit and drill about a half

an inch deep this will make sure the lag screws sit flush once those are drilled i take a smaller

bit and drill all the way through the center after clamping the 2×4 in place i add lag

screws and washers and this part is done at this point you can call it a day

it works as a seal row bench perfectly i'd like to make mine a little more comfortable

to use i'll be adding a removable pad to the top if you're new to upholstery don't let this

scare you off i only learned recently and i'm definitely not a pro but it's really not

that bad if that still didn't convince you you can try using a yoga mat or just use a face

pillow like this guy these long rib cuts are much easier with the table saw but can also

be done with a circular saw or even a jigsaw i lay the 2 by 12 on top of the plywood so i can

mark and drill my holes these holes don't have to be perfectly symmetrical but it helps if you think

you may want to remove the pad at some point i clamp my pieces together before drilling the holes

i'll be using quarter inch bolts to attach these pieces so i use a 3 8 inch forstner bit to give

myself a little extra room you want to at least go deep enough to hit the plywood underneath flip

it around and do the same thing on the other side once i'm through the 2 by 12 i move it and

drill the rest of the way through the plywood i'm using prolonged t-nuts to secure the bolts

for the pad these just hammer in super easy i flip the plywood over and lay the 2 by 12 over

the top you'll want to make sure the holes line up before you move on to the next step mine line

up perfectly it's time to add the padding i'm using one inch thick foam if you want more

padding you can go thicker or just double up the foam will go on the same side as the t-nuts i

spray some adhesive down before placing the foam my foam is not quite long

enough but that's an easy fix i can use a scrap piece to

fill in the missing part the material i used to cover the foam is some

sort of fake vinyl i got a large roll for pretty cheap on amazon you'll want an excess

of about two and a half inches on each side after cutting the material i'm ready to staple it the trick to using the stapler is that you need to have the right staples and

the proper amount of pressure i'm using half inch staples because my plywood is

half inch the staple gun is powerful so i turn the pressure down pretty low you should make sure

to test the pressure before starting this step once that is set you just lay the fabric down

and staple be careful not to staple your fingers corners are tricky and i still haven't

figured out how to make them look good but as long as the staples

hold the fabric down it's fine i spray paint the 2 by 12 piece black before

attaching the pad i don't bother spraying the part that will be covered by the pad this next part is

super easy as long as your holes line up properly once the bolts are secure this thing is good to go you can do seal rows with dumbbells you can do

them with straight bars or even a curl bar but i prefer to use a camber bar because of the extra

range of motion they allow i currently have two camber bars bells of steel's arch nemesis swiss

bar and the titan multi-grip camber bar both cost around 200 and are great to have around the home

gym so that's it let me know what you think in the comments section below thanks for watching

don't forget to like comment and subscribe you

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.