This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.

Milwaukee cordless tools have become a staple in the tool industry, renowned for their quality and reliability. But have you ever wondered where these impressive tools are actually made? In this article, we will explore the fascinating origins of Milwaukee cordless tools and uncover the manufacturing secrets behind their exceptional craftsmanship. From the bustling factories to the intricate processes, get ready to discover the heart and soul behind these innovative tools that have revolutionized the way we work.

Overview of Milwaukee Cordless Tools

Introduction to Milwaukee Cordless Tools

Milwaukee Cordless Tools is a leading manufacturer of high-quality power tools. Known for their durability, performance, and innovation, Milwaukee Cordless Tools have become a popular choice for professionals and do-it-yourselfers alike. With a range of cordless tools including drills, saws, and impact drivers, Milwaukee offers a comprehensive line of products to meet the needs of various industries and applications.

Importance of Knowing Where Tools Are Made

When it comes to purchasing power tools, knowing where they are made can be an important factor for many consumers. The country of origin can provide insight into the quality and durability of the products. Additionally, the location of manufacturing facilities can have implications on job creation, economic impact, and customer service. Understanding where Milwaukee Cordless Tools are made can help consumers make informed decisions and support local industries.

History of Milwaukee Tools

Origins of Milwaukee Tools

Milwaukee Tools traces its roots back to 1924 when A.H. Peterson founded the Milwaukee Electric Tool Corporation. The company initially focused on manufacturing lightweight, portable electric tools aimed at improving productivity in various industries. Over the years, Milwaukee Tools gained a reputation for producing reliable and innovative products, establishing a strong presence in the power tool market.

Milestones and Innovations

Throughout its history, Milwaukee Tools has achieved several milestones and introduced groundbreaking innovations. In 1951, the company introduced the first portable, one-handed ¼-inch capacity drill, revolutionizing the industry. Milwaukee Tools continued to innovate with the introduction of the first-ever portable, battery-operated tool in 1961, marking the birth of cordless power tools. Since then, Milwaukee Tools has consistently pushed the boundaries of tool design and performance, earning the trust of professionals around the world.

Expansion and Global Presence

As Milwaukee Tools continued to grow and innovate, the company expanded its operations globally. In addition to the United States, Milwaukee Tools established manufacturing facilities and distribution centers in Europe, Asia, and other regions. This global presence has allowed Milwaukee Tools to reach a wide range of customers and cater to the specific needs of different markets.

Manufacturing Facilities

Domestic Manufacturing Facilities

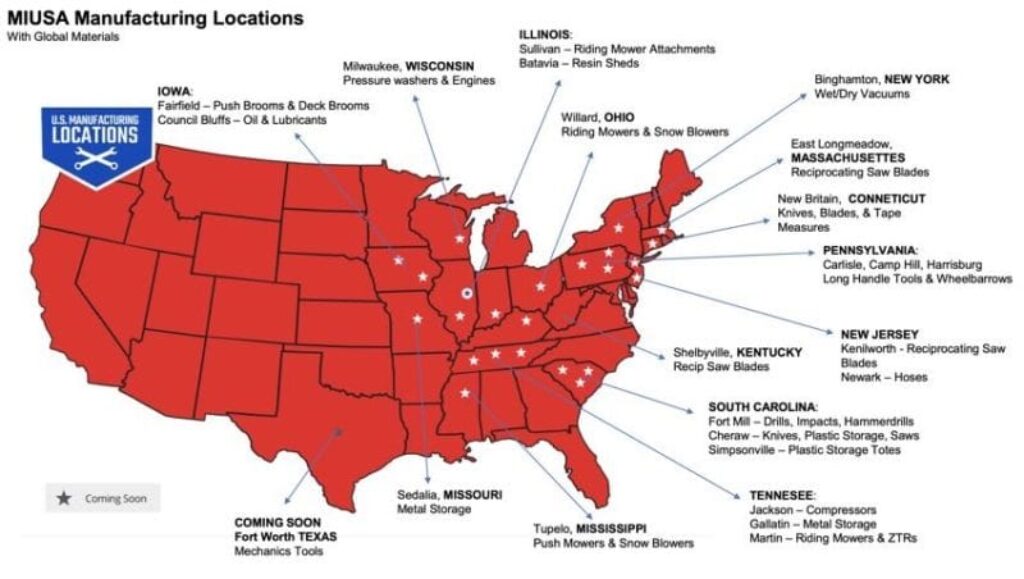

Milwaukee Tools takes pride in its commitment to domestic manufacturing. The company has several manufacturing facilities located throughout the United States, including in Wisconsin, Mississippi, and Arkansas. These facilities play a crucial role in producing a significant portion of Milwaukee Cordless Tools. By manufacturing products domestically, Milwaukee Tools can closely monitor quality control, ensure efficient production processes, and support local economies.

International Manufacturing Facilities

In addition to domestic manufacturing facilities, Milwaukee Tools operates manufacturing facilities in various countries around the world. These international facilities enable the company to meet the demand for its products in global markets. By strategically locating manufacturing facilities, Milwaukee Tools can optimize production and distribution processes, ensuring timely delivery of products to customers worldwide.

Quality Control and Testing

Milwaukee Tools is dedicated to maintaining the highest levels of quality control and product performance. Each manufacturing facility, both domestic and international, adheres to rigorous quality standards and undergoes regular testing. This commitment to quality ensures that every Milwaukee Cordless Tool meets the company’s stringent specifications and exceeds customer expectations.

Benefits of Domestic Manufacturing

Job Creation and Economic Impact

One of the significant benefits of domestic manufacturing is its contribution to job creation and the local economy. By operating manufacturing facilities in the United States, Milwaukee Tools supports a wide range of employment opportunities, from production line workers to engineers and technicians. These jobs not only provide income for individuals and their families but also contribute to the overall economic growth of the communities in which the facilities are located.

Response Time and Customer Service

Domestic manufacturing allows Milwaukee Tools to have more control over its production timelines and ensure efficient response times to customer needs. With manufacturing facilities located within the United States, the company can quickly produce and distribute new products, meet increased demand, and respond effectively to customer inquiries or issues. This fast response time enhances customer satisfaction and builds trust in the Milwaukee Cordless Tools brand.

Leaning towards Local Products

In recent years, there has been a growing trend among consumers to support local businesses and products made in their own countries. By manufacturing Milwaukee Cordless Tools domestically, the company appeals to these preferences and taps into the sentiment of buying local. This aspect can further enhance the reputation and desirability of Milwaukee Tools, especially among those who value supporting domestic industries.

Challenges of Domestic Manufacturing

Higher Labor Costs

Domestic manufacturing typically requires higher labor costs compared to outsourcing production to overseas markets. Factors such as wages, benefits, and labor regulations can contribute to increased expenses. While this poses a challenge for Milwaukee Tools, the company recognizes the benefits of domestic manufacturing and continues to invest in its domestic facilities to maintain quality and customer satisfaction.

Competition from Overseas Markets

In today’s globalized economy, Milwaukee Tools faces competition from power tool manufacturers based in overseas markets. These manufacturers often benefit from lower operating costs, allowing them to offer products at competitive prices. To stay competitive, Milwaukee Tools must continually innovate, streamline production processes, and focus on quality to differentiate itself in the global market.

Supply Chain Complexities

The complexity of managing a global supply chain presents a challenge for Milwaukee Tools. Coordinating production, distribution, and inventory across multiple manufacturing facilities and regions requires careful planning and execution. Any disruptions or inefficiencies in the supply chain can impact the availability and delivery of Milwaukee Cordless Tools to customers. However, the company’s experience in global operations has enabled it to develop robust supply chain management strategies to mitigate these challenges.

Impact of Globalization on Milwaukee Cordless Tools

Outsourcing Manufacturing to Overseas Markets

In response to market demands and cost considerations, Milwaukee Tools, like many companies, has outsourced some of its manufacturing to overseas markets. By partnering with manufacturers in these regions, Milwaukee Tools can benefit from lower production costs while still maintaining quality control. This strategic approach allows the company to stay competitive in the global marketplace and expand its reach to international customers.

Risks and Benefits of Global Manufacturing

Outsourcing manufacturing to overseas markets comes with both risks and benefits for Milwaukee Tools. While the lower production costs can be advantageous, there are inherent risks associated with quality control, intellectual property protection, and time zones. However, by selecting reputable manufacturers and implementing stringent quality control processes, Milwaukee Tools minimizes these risks and focuses on the benefits gained from global manufacturing.

Distribution and Sales Channels

Channels for Domestic Distribution

To ensure widespread availability and convenient access to their products, Milwaukee Tools employs a variety of distribution channels in the United States. These include partnerships with national retailers, independent hardware stores, and online marketplaces. By utilizing a diverse range of distribution channels, Milwaukee Tools can cater to the preferences and purchasing habits of different consumer segments.

Channels for International Distribution

Milwaukee Tools’ global reach extends to international distribution channels as well. The company collaborates with authorized distributors and retailers in various countries to make its cordless tools accessible to customers worldwide. This network of distribution channels ensures that Milwaukee Cordless Tools can be purchased and serviced in numerous markets, regardless of geographical location.

Consumer Perceptions and Preferences

Perceptions of Made in the USA Products

The perception of “Made in the USA” products often carries positive connotations, particularly regarding quality, durability, and support for local industries. Many consumers place value on purchasing products that are made domestically, as it aligns with their preference for supporting local businesses and the economy. Milwaukee Cordless Tools’ commitment to domestic manufacturing can appeal to these consumer perceptions and solidify the brand’s reputation.

Factors Influencing Purchase Decisions

When it comes to purchasing cordless tools, consumers consider various factors. While the quality and performance of the product are primary considerations for most, other factors such as price, brand reputation, and customer service also play a role. Milwaukee Tools’ domestic manufacturing facilities positively impact consumer preferences, as they ensure high levels of quality control, prompt customer service, and support local job opportunities.

The Future of Milwaukee Cordless Tools Manufacturing

Technological Advancements

The future of Milwaukee Cordless Tools manufacturing holds exciting prospects for technological advancements. Milwaukee Tools continually invests in research and development to stay at the forefront of innovation in the power tool industry. As technology evolves, so too do the capabilities of Milwaukee Cordless Tools. The integration of smart features, improved battery technology, and enhanced ergonomics are all areas where Milwaukee Tools can continue to excel.

Sustainability and Environmental Considerations

In recent years, sustainability has become an increasingly important factor in consumers’ purchasing decisions. Milwaukee Cordless Tools’ manufacturing processes can embrace sustainable practices such as energy-efficient production methods and responsibly sourced materials. By prioritizing sustainability, Milwaukee Tools can demonstrate its commitment to environmental responsibility and appeal to the growing segment of environmentally conscious consumers.

Adapting to Market Trends

The power tool market is dynamic and constantly evolving. To remain competitive, Milwaukee Cordless Tools must adapt to changing market trends and consumer demands. This includes staying informed about emerging technologies, understanding user preferences, and adjusting product offerings accordingly. By keeping a pulse on the market, Milwaukee Tools can continue to innovate and provide cordless tools that meet the evolving needs of professionals and consumers.

Conclusion

Milwaukee Cordless Tools has a storied history of innovation and manufacturing excellence. With domestic and international manufacturing facilities, the company is poised to meet the demand for its high-quality cordless tools worldwide. While domestic manufacturing offers benefits such as job creation and improved response times, it also presents challenges such as higher labor costs and competition from overseas markets. Milwaukee Tools has successfully navigated these challenges and leveraged the benefits of global manufacturing. As the company looks to the future, it will continue to prioritize technological advancements, sustainability, and adaptability to ensure its position as a leader in the power tool industry. When considering the purchase of Milwaukee Cordless Tools, customers can rest assured that they are investing in reliable, innovative tools that support local economies and provide exceptional performance.

This post may contain affiliate links which means I may receive a commission for purchases made through links. Learn more on my Private Policy page.